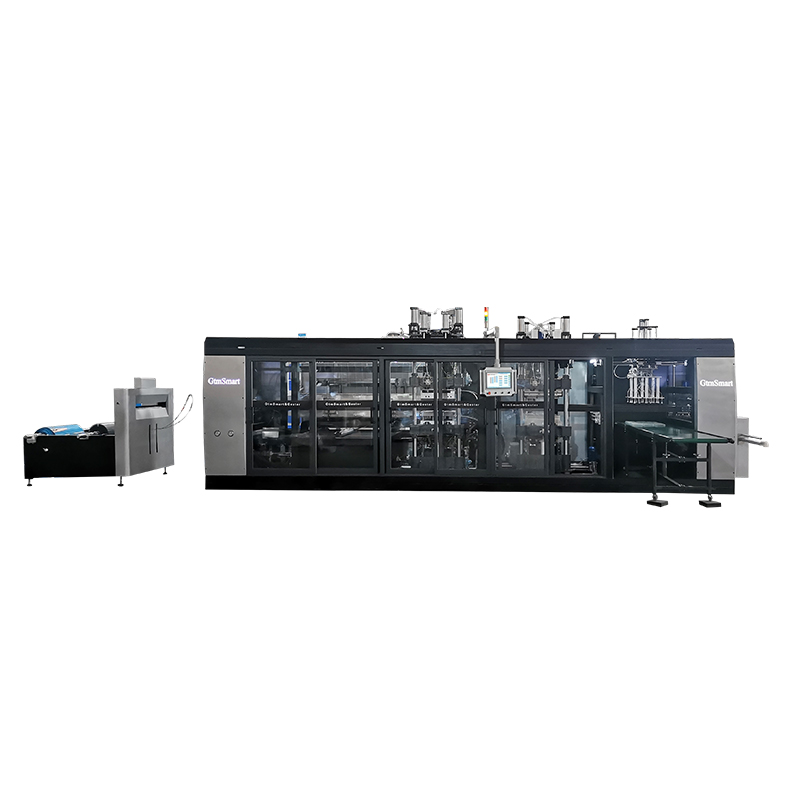

Product Introduction

Automatic thermoforming machine is a new type of machine developed by our company according to the market and customer's demand. The machine is a kind of multi-station automatic machine, which has the synchronous complete forming, punching, and cutting, so easy to get the end plastic products. Therefore, the input of labor and the cost of production is greatly reduced, and the work efficiency is much more improved.

Application

This thermoforming machine used for producing high demand of disposable fresh/fast food, fruit plastic cups, boxes, plates,container, and pharmaceutical, PP, PS, PET, PVC,etc.

Feature

1. This thermoforming equipment fully servo driven machine.no noise.no vibration,forming good and fast.

2. Fully machine in compact structure,taking small floor space;

3. Furnaces automatic removal device,can be turned down at any time during production without breaking the sheet.reaching without wasting materials;

4. Electric furnace temperature control system uses intelligent automatic compensation control,a control,a control of a regulator,easy to adjust the temperature uniformity,easy to use,simple,fast heating,low temperature three times up and down the oven roast slices.

5. Forming, cutting die servo-driven,two-way adjustable for upper and lower mold stroke,in which the upper mold electric adjustable in clamping direction. The upper and bwer molds height position can be adjusted conveniently and fast under the clamping state;lower mold in clamping direction readily accessible buffer,increasing the clamping speed,avoiding shock.

6. Thermoformer machine auto cutting,auto counting,auto transmission by PLC.

Key Specification

| Model | HEY02-6040 | HEY02-6850 | HEY02-7561 |

| Max.Forming Area (mm2) | 600x400 | 680x500 | 750x610 |

| 4 Stations | Forming, Cutting, Punching, Stacking | ||

| Sheet Width (mm) | 350-720 | ||

| Sheet Thickness (mm) | 0.2-1.5 | ||

| Max. Dia. Of Sheet Roll (mm) | 800 | ||

| Forming Mould Stroke(mm) | Upper Mould 150, Down Mould 150 | ||

| Power Consumption | 60-70KW/H | ||

| Forming Mould Width (mm) | 350-680 | ||

| Max. Formed Depth (mm) | 100 | ||

| Cutting Mould Stroke(mm) |

Upper Mould 150, Down Mould 150 | ||

| Max. Cutting Area (mm2) | 680×500 | ||

| Cutting Force (ton) | 40 | ||

| Dry Speed (cycle/min) | Max 30 | ||

| Product Cooling Method | By Water Cooling | ||

| Vacuum Pump | UniverstarXD100 | ||

| Power Supply | 3 phase 4 line 380V50Hz | ||

| Max. Heating Power | 121.6 | ||

| Max. Power of Whole Machine (kw) | 150 | ||

| Max. Machine Dimension(L*W*H) (mm) | 11150×2300×2700 | ||

| Weight of Whole Machine ( T ) | ≈11 | ||

Send your message to us:

Products Recommended

More +-

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc)... -

Model: HEY01

Model: HEY01High Speed Automatic Pressure PET Thermoforming Machine

Product Introduction This High Speed Automatic Pressure PET Thermoforming Machine adopts the method of laminating heating, adopts the technology of moving film punching, no secondary pollution, hig... -

Model: HEY01

Model: HEY01Three Station Fully Automatic Plastic Thermoforming Machine

Product Introduction Fully Automatic Thermoforming Machine: Integrated heating, forming, punching and stacking stations. Thermoformer use high-efficiency ceramic heating elements; laser knife mold,...