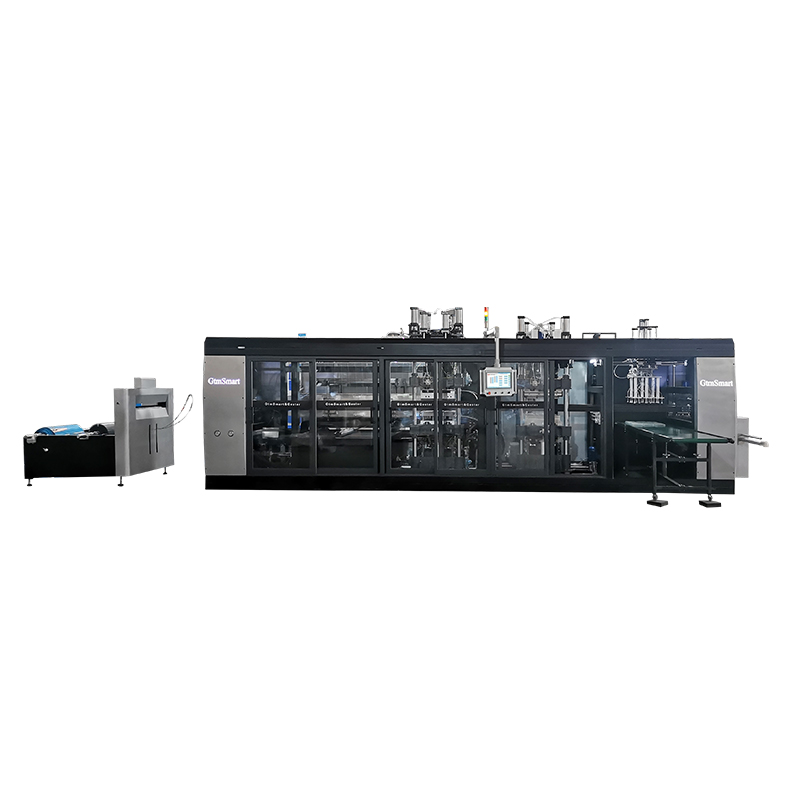

Product Introduction

This High Speed Automatic Pressure PET Thermoforming Machine adopts the method of laminating heating, adopts the technology of moving film punching, no secondary pollution, high sanitary level, high production safety coefficient, saving labor, the equipment set positive pressure/negative pressure/positive and negative pressure automatic molding, punching, cutting, manipulator grasp stack counting in a production line to complete continuously, automatic conveying products.There is no need for manual punching, manual cutting and other subsequent processing procedures, reduce a series of quality problems caused by manual punching and cutting and cumbersome subsequent procedures, save the site, reduce secondary pollution, save labor costs, product quality has been greatly improved.

Feature

1.Pet Thermoforming Machine : High speed, low noise, durable, easy maintenance; Max. Speed 30 cycle/minute.

2.Servo system control for stretching, suitable for PS, HIPS, PVC, PET, PP, etc material manufacture.

3.Pressure Thermoforming Machine: New design tool changing system, easy to charge the mould & tool in punching & stacking station, ensure the maximized production time.

4.Advanced heating system with latest moulders for temperature control, for fast reaction time, resulting in high efficiency and low production cost.

Pet Thermoforming Machine Key Specification

| Model | HEY01-6040 | HEY01-7860 |

| Max.Forming Area (mm2) | 600x400 | 780x600 |

| Working Station | Forming, Cutting, Stacking | |

| Applicable Material | PS, PET, HIPS, PP, PLA, etc | |

| Sheet Width (mm) | 350-810 | |

| Sheet Thickness (mm) | 0.2-1.5 | |

| Max. Dia. Of Sheet Roll (mm) | 800 | |

| Forming Mould Stroke(mm) | 120 for up mold and down mold | |

| Power Consumption | 60-70KW/H | |

| Max. Formed Depth (mm) | 100 | |

| Cutting Mould Stroke(mm) | 120 for up mold and down mold | |

| Max. Cutting Area (mm2) | 600x400 | 780x600 |

| Max. Mold Closing Force (T) | 50 | |

| Speed (cycle/min) | Max 30 | |

| Max. Capcity of Vacuum Pump | 200 m³/h | |

| Cooling System | Water Cooling | |

| Power Supply | 380V 50Hz 3 phase 4 wire | |

| Max. Heating Power (kw) | 140 | |

| Max. Power of Whole Machine (kw) | 160 | |

| Machine Dimension(mm) | 9000*2200*2690 | |

| Sheet Carrier Dimension(mm) | 2100*1800*1550 | |

| Weight of Whole Machine (T) | 12.5 | |

Send your message to us:

Products Recommended

More +-

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc)... -

Model: HEY01

Model: HEY01Three Station Fully Automatic Plastic Thermoforming Machine

Product Introduction Fully Automatic Thermoforming Machine: Integrated heating, forming, punching and stacking stations. Thermoformer use high-efficiency ceramic heating elements; laser knife mold,...