x

Application

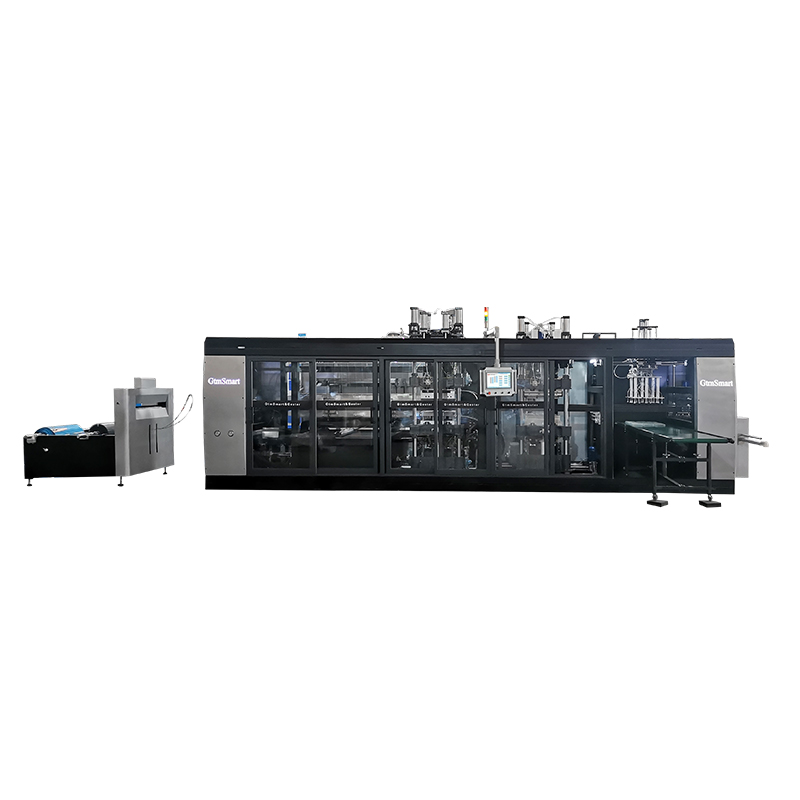

This sheet extrusion line to manufacture PP/HIPS Disposables containers like cup, tray, lid, multi-compartment plate and hinged containers etc. from PP/HIPS Sheet.

Total Requirement

| Electrical require | 380V Three-phase 50HZ |

| Available Material | PP/HIPS |

| Max Sheet Width | 850mm |

| Sheet Thickness | 0.3-2.0mm ±0.01mm |

| (HIPS)Max Output(HIPS) | 400-500kg/h |

| Sheet Production Line Speed | 5-35m/min |

| Total Power | 350kw Actually 300kw |

| Consumption Of Compressed Air | 1M3/H 0.5-0.7Mpa |

Main Components

| NO. | Parts of the Machine Unit | Unit | QTY |

| 1 | Single Screw Sheet Extruder | set | 1 |

| 2 | Plate Style Hydraulic Net-changing Device | set | 1 |

| 3 | Metering Pump | set | 1 |

| 4 | Inclined Tablet Press Machine | set | 1 |

| 5 | Roller Constant Temperature Device | set | 1 |

| 6 | Margin Cutting Device | set | 1 |

| 7 | Waste Winding Device | set | 1 |

| 8 | Tractor | set | 1 |

| 9 | Double Stations Sheet Roll Winding Machine | set | 1 |

| 10 | PLC Control Cabinet | set | 1 |

Detail Specifications for Device and Components

| f120Sheet Extruder | |

| Material of Barrel Screw | 38CrMnAIA |

| Quenching-temper Treatment | HB320-350 |

| Surface Hardness of Screw | HV950-1050 |

| Diameter of Screw | Ø120mm |

| Max. Output | 380-450Kg/H |

| Screw L/D rate | L/D 36:1 |

| Screw Structure | Separate Structure |

| Rotation Speed of Screw | 20-92r/min |

| Barrel Heating Areas | 7Areas |

| Total heating power | 50kw |

| Heating method | Ceramic Heating Ring with Stainless Cover |

| temperature control meter | Fuji Japan |

| Solid State Relay | Yangming Taiwan |

| cooling method | Wind cooling, cooling fan is 0.37KW*7 |

| Driving Motor | WNM MOTOR 132kw |

| Frequency Converter | Innovation |

| Reducer | 16:1 |

| Reducer Connects with Motor | Directly, Coupling Connection |

| Plate Style Hydraulic Net Changer 1 set | |

| Plate Style Net-Changer | f150 |

| Pressure of Hydraulic System | 16MPA Motor Power 2.2kw |

| Net-changing Structure | Single Plate with Double Holes |

| Heating Zone | 1 Area |

| Heating Power | 3kw |

| Metering Pump 1 set | |

| Metering Pump Rotation Speed | 6-50r/min |

| Displacement of Metering Pump | 200CC |

| Heating Power | 8kw |

| Driving Motor | 11kw |

| Frequency Conversion Speed Regulator | Innovation |

| Pressure Sensor | Italy GEFRAN |

| TheJ.C time | |

| Valid Width of Die | 950mm |

| Die Lip Opening Size | 2.0 mm |

| Heating Areas of Die Head | 5Areas |

| Die Head Material | 5CrNiMo |

| Heating Power | 15kw |

| Form of Die | Coat Hanger Type |

| Mould Cavity Treatment | Surface chrome-plating and polishing treatment. Thickness of plated chrome layer is more than 0.06mm after polished.And roughness of surface is more than ▽12 |

| Horizontal Three Rollers Calender | |||

| Speed | 4-35m/min | ||

| Size of Upper Roller | φ315mm*1000m*1 | ||

| Diameter of Middle Roller and Down Roller | φ520mm*1000mm*2 | ||

| Material of Roller | (42CrMo) | ||

| Surface Roughness of Roller | Mirror Treatment Ra≤0.015um | ||

| Surface Hardness of Roller | ≥HRC60 | ||

| The Thickness of Chromium Coating | 0.08-0.12mm | ||

| Motor Power | 1.1kw | ||

| Converter Reducer | GNORD | ||

| Servo Motor | INOVANCE | ||

| Servo Controller | INOVANCE | ||

| Way to adjust the rollers distance | Hydraulic Cylinder Adjustment, | ||

| Three Rollers Bearing | NSK | ||

| Roller Temperature Controller | |||

| Cooling Medium | Water | ||

| Temperature Controlling Range | Ordinary Temperature to 90℃ | ||

| Temperature Control | ≤±1℃ | ||

| Heating Roller | 6KW/Set*3 sets, Stainless Steel | ||

| Water Pump Power | 3KW Three High Pressure Water Pump | ||

| Edge Cutting Device | |||

| Structure of Cutter | Light Knife | ||

| QTY | Two knifes for left and right sides,which can quickly adjust distance independently | ||

| Waste Edge Winding | Torque Motor and RV reducer be connected directly | ||

| Tractor | |||

| Speed | 4-35m/min | ||

| Down Steel Roller/Upper Rubber Roller | The Thickness of NBR on the Surface of Roller is 20mm, surface shore hardness is between 65-70° | ||

| Rollers Model | Ф205mm×1000mmФ215mm×1200mm | ||

| Converter Reducer | GNORD | ||

| Servo Motor | INOVANCE | ||

| Servo Controller | INOVANCE | ||

| Double Stations Central Winding Machine | |||

| Winding Method | Central Winding by Air Expansion Shaft | ||

| Winding Power | Torque Motor | ||

| Tile Type Air Expansion Shaft | φ75×1000mm×2 | ||

| Dia. Of Winding Sheet | ≤φ1000mm | ||

| Width of Winding Sheet | ≤1000mm | ||

Controlling System

- Adopts INOVANCE PLC control, reflects the intelligent centralized control of the whole machine, indirect control circuit,and superior performance.

- Plastic sheet machine temperature controlled by Japan Fuji temperature-controlled meter PID, which precision can reach to ±1℃.

- Extruder main motor utilize WNM AC MOTOR, and control by INOVANCE frequency conversion speed regulator.

- Roller use GNORD converter reducer, which drive independently with servo motor,controlled by servo controller.

- Sheet extrusion line: High precision motion control function, convenient modular structure.

- Multilingual operating system, also have customized design.High intelligent machinery, simple operation.

- Other electrical brand of control system: Schneider Contactor, Schneider Thermo Relay, Schneider select switch and press-button, Schneider air switch, Taiwan Yangming Solid State Relay.

Applications

Send your message to us:

Write your message here and send it to us

Products Recommended

More +-

Model: HEY01

Model: HEY01PLC Pressure Thermoforming Machine With Three Stations HEY01

PLC Pressure Thermoforming Machine With Three Stations HEY01 Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit cont... -

Model: HEY03

Model: HEY03Single Station Automatic Thermoforming machine HEY03

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc)... -

Model: HEY11

Model: HEY11Hydraulic Servo Plastic Cup Thermoforming Machine HEY11

Hydraulic Servo Plastic Cup Thermoforming Machine HEY11 Cup Thermoforming Machine Application The whole Plastic Cup Thermoforming Machine Mainly for the production of variety plastic containers (... -

Model: HEY12

Model: HEY12Full Servo Plastic Cup Making Machine HEY12

Full Servo Plastic Cup Making Machine cup making machine Application The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers,... -

Model: HEY05

Model: HEY05Plastic Vacuum Forming Machine HEY05

Vacuum Thermoforming Machine Description Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is shape...